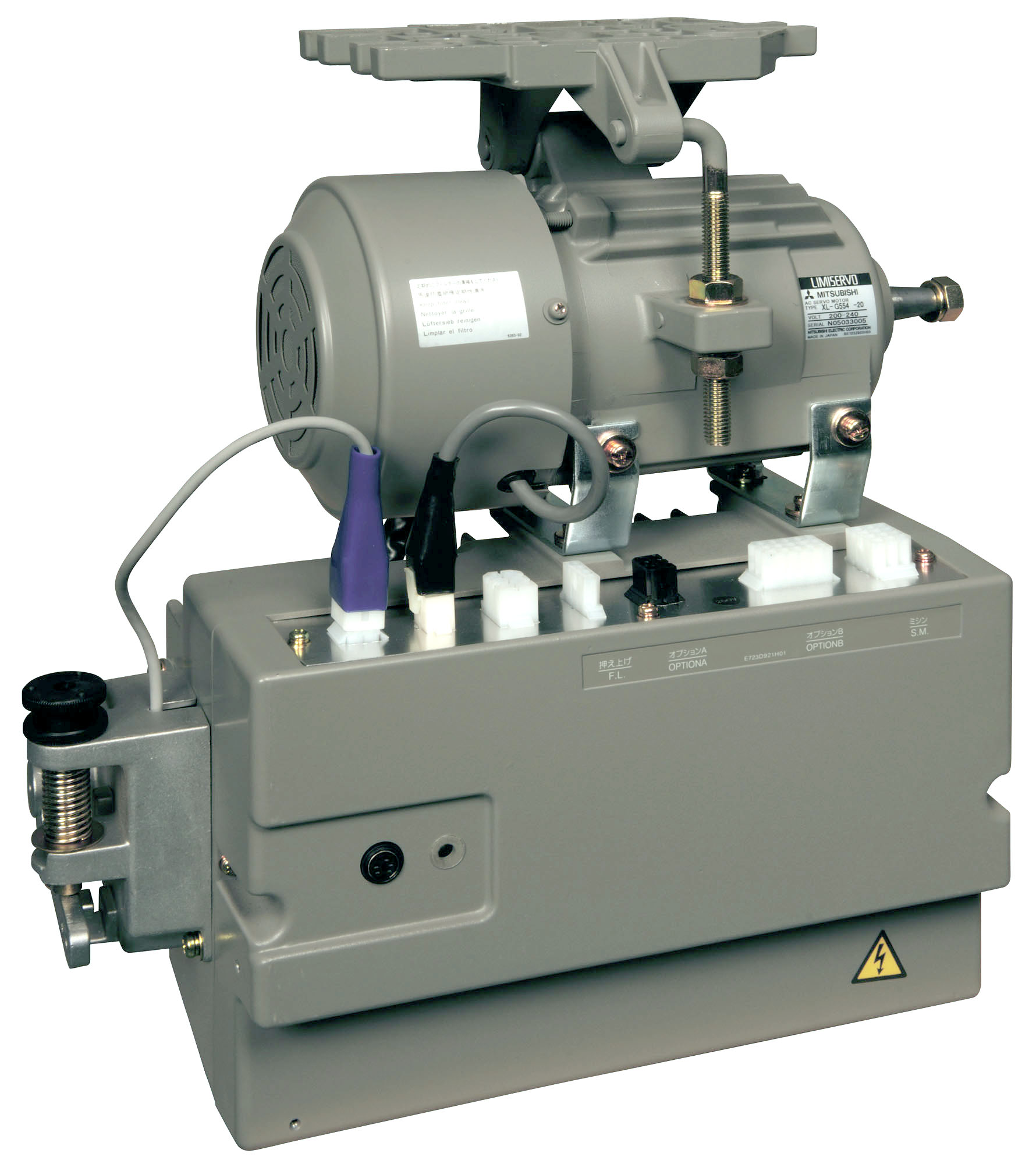

| Drive Unit LIMISERVO XC-G series LIMISERVO XC-G Series : Induction type AC Servo Motor and Control Box |

|

| * | Motor size and weight reduction |

| *Realization of compact. lightweight motor Motor size reduced by approximately 60% when compared with previous motor (XL-554). Motor weight reduced by approximately 1.7kg. |

|

| * | Enhanced functionality |

| *Step sequence function -This function enables easy programming of the desired input, output and machining operation in sequence with the stitching process. (Extensive upgrade of existing machine simple sequence mode) -Various operations can now be incorporated into the "stitching process", including those performed before and after operation. *Direct parameter No. call-up function Previously it was necessary to select the respective mode to perform settings when making changes to the parameters, however, by using the G10 or G500-Y control panel, it is now possible to call up the required parameter in a single operation. It is also possible to call up parameters for each mode. |

|

| * | User-friendly function |

| *Compute interface standard equipment -Settings data control including batch writing, reading and saving of settings can be performed using the setup software. (XCG_SET) -Step sequence creation, editing, etc. can be performed using the dedicated step sequence software. (XCG_STEP) |

|

| * | Multi-function, Interchangeability |

| *Full functionality -The G series retains all the operability and multi-functionality of the XC-F series! The control box uses the same connectors as the XC-F series, enabling easy connection. -The settings data save function has been expanded to enable saving of settings data from 1 model to 2 models. -A parameter change difference display has been added. (A flashing dot ( . ) displays at the changed parameter.) -2 types of function setting can now be performed with a single input. *Interchangeability The XC-KE-01P detector, LE-FA presser foot lifter units and XC-CVS-3 variable speed pedal can all be used as is. The XL-554 motor can be used with an optional attachment bracket. *Control panel XC-G10 and XC-G500-Y series control panels are available. The existing operation panel can be attached to and removed from the XC-G10 series control panel. Significant enhancements have been made to the operability of the XC-G500-Y series control panel over existing functionality (XC-E500-Y), and the settings data memory has been doubled. |

| Type | Motor Connector |

Power Supply | Output(W) | Output Shaft | Mass | |

| Number of phases | Voltage(V) | |||||

| XL-G554-10Y | Strain relief | Single phase | 100 to 120 | 550 | Taper shaft | 6.9Kg (net) 9.1kg (gross) |

| XL-G554-20Y | Three phases Single phase(*1) |

200 to 240 | ||||

| XL-G754-20Y | 750 | |||||

| Type | Output | Power supply | Function | Mass | |

| Number of phases | Voltage | ||||

| XC-GMFY-10-05 | 550W | Single phase | 100-120 | Full functionality including auto thread trimming, presser foot lifting, fixed-stitch stitching, continuous stitching and backtacking. Equipped with step sequence, simple sequence and computer communication functions (when connected to control panel). Equipped with 8 solenoid drive outputs, 2 electromagnetic valve outputs, 1 small-signal output and 14 input terminals including a variable voltage input. | 3.5Kg (net) 6.9kg (gross) |

| XC-GMFYCE-20-05(*2) | 200-240 | ||||

| XC-GMFY-20-05 | Three phase/ Single phase(*1) |

||||

| XC-GMFY-20-07 | 750W | ||||

Note2:Type [XC-GMFYCE] is CE marking type (*2)

| Control panel | XC-G10S [control box attachment type (One unit is standard equipment.)] XC-G10L XC-G500-Y ("XC-G500-Y" and "XC-G10" cannot be used together.) |

| Auto presser foot lifter unit | LE-FA : Pneumatic type (common for 30V/24V) |

| Variable speed pedal | XC-CVS-3 : 3-speed pedal, for standing operation sewing machine |

| Extension cables | Motor cable 1.0m : K14M52158002 Detector cable 0.6m : K14M71324830 Encoder cable 1.0m : K14M71725402 |

| Installation metal fittings | XL-G554 motor and old control box : K14M72354001 Old motor and XC-GMFY control box : K14M72354101 |

| * | Reference material |

| * Practical Application for function setting (PDF data) * Blinking pattern of LED on front cover and Error code (PDF data) |

All Rights Reserved, Copyright (C) Meiryo Technica Corporation 2003.